-

Call us

-

Send Us Mail

The Ultimate Guide to RONCO PrimaCut™ Cut-Resistant Gloves

When it comes to personal protective equipment (PPE), cut-resistant gloves are vital to ensuring safety in industries with exposure to environments that require working with sharp objects and high-risk tasks. RONCO’s PrimaCut™ line of cut-resistant gloves not only offers superior protection but also provides comfort and precision for various industrial applications.

Understanding how these gloves protect against hazards requires looking at the ANSI/ISEA 105 standard, a widely recognized system for assessing cut resistance and other protective features. Before diving into the product highlights, let’s take a closer look at the ANSI standard and why it matters.

ANSI/ISEA 105 Cut Resistance Levels

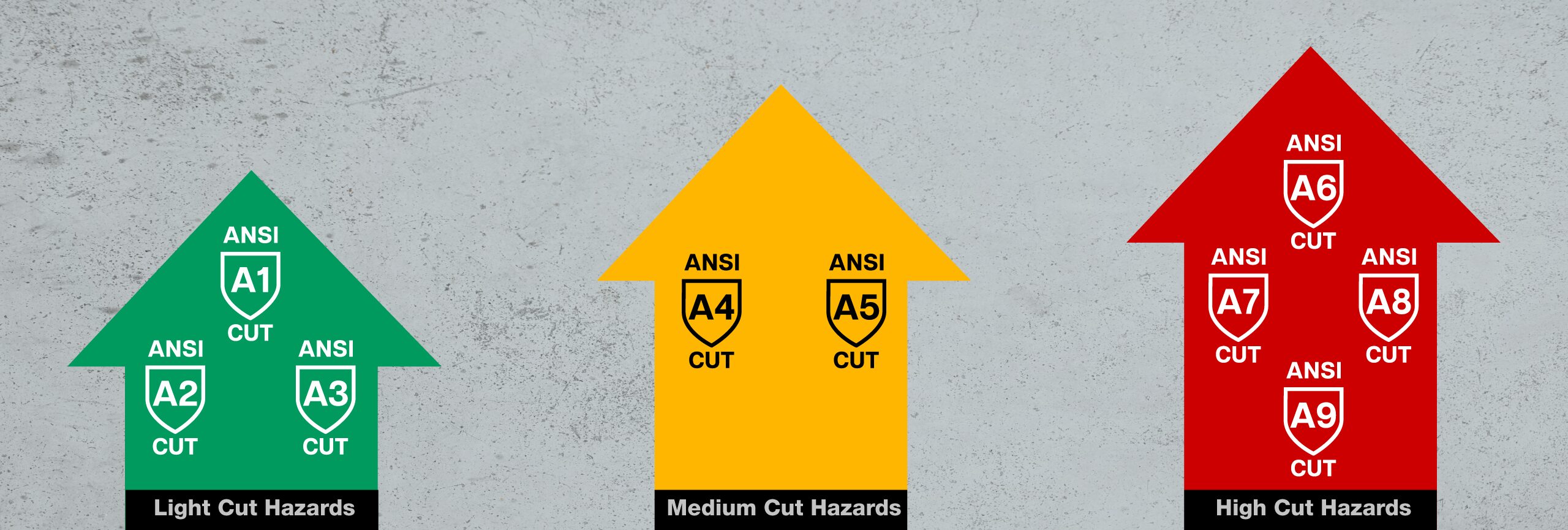

The ANSI/ISEA 105 standard categorizes cut resistance into different levels, ranging from A1 to A9, depending on the grams of force needed to cut through the glove material. Gloves are tested by applying force to sharp objects and observing the point at which the material is penetrated. This standardized test ensures consistency in safety ratings across various products and manufacturers.

Below is a description of cut levels, A1 to A9:

- A1 to A3: Protection against light cut hazards, such as handling small parts or material with minimal sharp edges.

- A4 to A5: Offers moderate protection, suitable for tasks like glass handling, sheet metal work, and light industrial manufacturing.

- A6 to A9: Designed for high-risk environments involving sharp metal, glass, and hazardous sharp materials, including applications in industries like automotive, recycling, and meat processing.

Now that we’ve reviewed the ANSI cut levels, let’s look at a few styles of RONCO’s PrimaCut™ gloves and how they meet these stringent safety standards while delivering comfort and sustainability.

PrimaCut™ 69-510 Gloves

These gloves are rated A4 under ANSI’s cut resistance scale, making them suitable for environments where moderate cut risks are present. They are crafted as a cut resistant liner that provides enhanced protection without sacrificing dexterity. This balance makes the PrimaCut™ 69-510 ideal for food processing, sharp edge material handling, meat cutting and deboning, construction, and light assembly tasks. For industries requiring precision and safety, this glove is the perfect fit.

PrimaCut™ 69-680E Gloves

The PrimaCut™ 69-680E model stands out for its sustainability as it is made from recycled PET bottles. Rated A2 for cut resistance, these gloves are ideal for low-risk environments where tear resistance is critical. The eco-friendly construction combines comfort, grip, and protection, making it an excellent choice for tasks involving small parts, general purpose applications, carpentry, warehousing or light industrial work.

PrimaCut™ 69-594W Gloves

The 69-594W is designed for extreme cold conditions, with ANSI A5 cut protection. Acrylic lining provides extreme cold protection, offering warmth and safety, making these gloves a reliable option for outdoor work in harsh environments like marine, construction, solid waste collection & handling, glass & building materials, machinery & equipment, automotive, municipal cleaning, or transportation & warehousing during the winter months. With its latex-coated finish, this glove ensures a secure grip even in wet or icy conditions, without compromising on cut resistance.

Glove Selection and Durability

The ANSI standard also assesses gloves for abrasion resistance, measured in the number of cycles required to wear through the material. PrimaCut™ gloves, tested for abrasion resistance, demonstrate exceptional durability, suitable for industries where repetitive handling of sharp objects is frequent. The gloves undergo rigorous testing to ensure they provide sustained performance over time.

Additionally, the puncture resistance rating, which determines how well gloves protect against punctures from sharp objects like nails or wire, is crucial for industries like recycling and waste handling. PrimaCut™ gloves meet these high standards, ensuring hands are shielded from various puncture hazards.

Conclusion

RONCO’s PrimaCut™ range of gloves sets the standard for cut resistance, durability, and comfort, meeting ANSI guidelines to keep workers safe across various industries. Whether your focus is on sustainable PPE solutions like the 69-680E, cold protection with the 69-594W, or versatile, high-performance gloves like the 69-510, RONCO’s cut resistant gloves line offer a reliable solution.

For more information on cut-resistant gloves explore our PrimaCut™ gloves collection. Stay protected with cutting-edge safety solutions engineered for today’s demanding work environments.

SIGN UP FOR OUR

NEWSLETTER

Learn how sustainable cut resistant sleeves deliver reliable arm protection comfort and durability while supporting environmental goals.

Match cut risk to the right cut level with PRIMACUT™ cut resistant gloves for manufacturing, designed for safety, dexterity & compliance.

Discover PRO-TEC™ NIOSH approved N95 respirators. Available in valved and non-valved options for comfort, compliance & 95% filtration.

Head Protection

Head Protection Hand Protection

Hand Protection Body Protection

Body Protection Sustainable Protection

Sustainable Protection VendPack®

VendPack®  RetailPack

RetailPack