-

Call us

-

Send Us Mail

A9 Cut Protection Without Compromise: The PrimaCut™ 69-9452 Advantage

When workers put on a glove, they’re not just covering their hands – they’re protecting their livelihood. Every day in industries like metal fabrication, recycling, glass handling, and construction, hands are exposed to hazards that can cause life-changing injuries. The challenge? Providing the highest cut protection possible without sacrificing comfort, dexterity, or productivity.

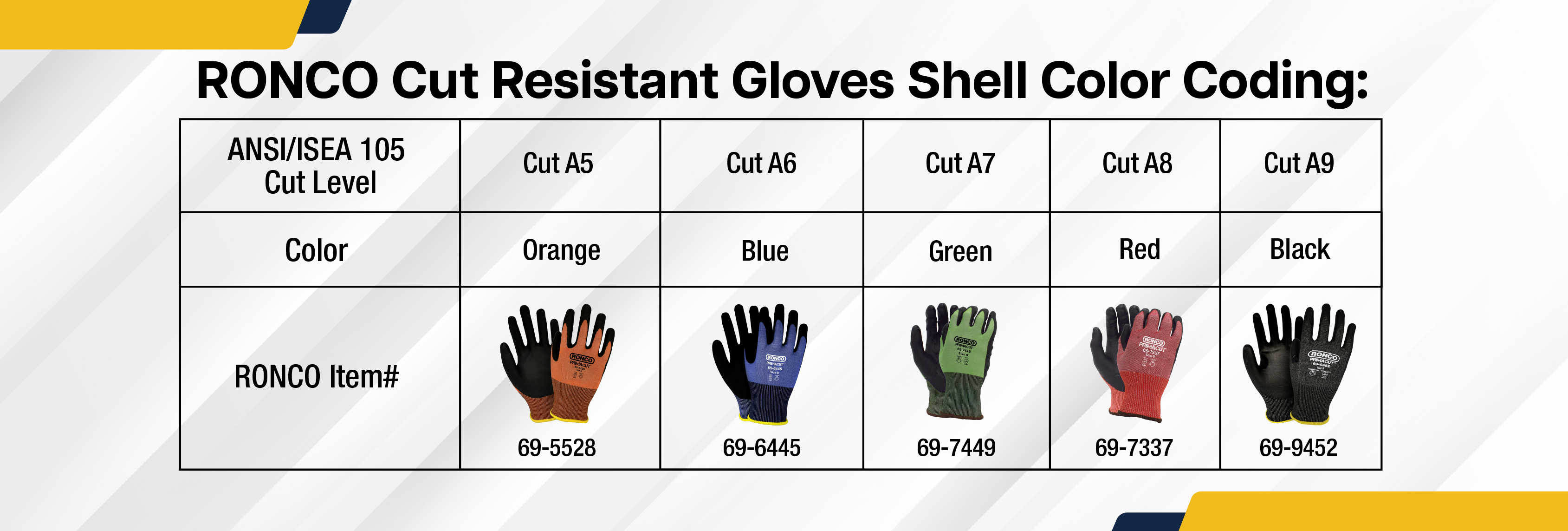

That’s exactly why we developed the PrimaCut™ 69-9452 utilizing RONCO’s new Color Cut Coding system. In this system, black signals ANSI/ISEA 105 Cut Level A9: the ultimate in cut resistance. This makes it one of the most trusted ANSI / ISEA 105 A9 cut resistant gloves on the market today.

In this article, we’ll break down:

• The hazards this glove was built to address

• The unique features that makes it different

• Real-world case studies of its impact

• The industries where it shines

• Why choosing “black” might be the most important safety decision you make this year

Understanding the Hazards: Where A9 Cut Resistant Gloves Matter Most

Cut-resistant gloves aren’t a luxury – they’re a necessity in high-risk environments. The PrimaCut™ 69-9452 is engineered for extreme hazards, making it ideal for anyone who needs A9 cut resistant gloves, including:

1. Sharp Metal Edges

In sheet metal handling, coil processing, and fabrication, razor-sharp edges can slice through unprotected hands in an instant.

2. Glass Sheet Handling

From architectural panes to automotive windshields, large glass sheets pose a double threat: sharp edges and potential breakage.

3. Recycling Operations

Scrap metal, broken bottles, and jagged debris require gloves that can handle both the unexpected and the unavoidable.

4. Heavy Equipment Maintenance

Mechanics and technicians often work around exposed blades, edges, and burrs where the wrong glove means an injury.

5. Construction & Demolition

These environments present a mix of hazards – sharp rebar, cut metal, splintered materials – that demand top-tier protection.

In all of these situations, A9 cut resistant gloves aren’t just preferable – they’re essential.

The PrimaCut™ 69-9452 Advantage in A9 Cut Resistant Gloves

We know that safety managers and procurement teams balance multiple factors when choosing PPE: protection level, comfort, worker acceptance, and cost. The 69-9452 hits all of these targets, making it a leading choice in A9 cut resistant gloves:

• 18-Gauge HPPE Liner – Offers the rare combination of maximum cut resistance and incredible dexterity.

• PU Palm Coating – Delivers precise grip for dry and lightly oily conditions, perfect for handling small parts or slick surfaces.

• Reinforced Thumb Saddle – A high-wear area that now lasts longer, reducing glove replacement frequency.

• Breathable & Seamless Fit – Keeps hands cooler, reduces sweat buildup, and minimizes fatigue.

• Touchscreen Capability – Eliminates the need to remove gloves for device use, keeping protection in place all shift long.

• Reliable durability and puncture resistance for extended glove life in tough jobs.

Case Study: Enhancing Safety and Productivity at an Ontario Metal Processing Plant

The Challenge: Persistent Cut Hazards

A large metal processing plant in Ontario was facing a significant and costly problem: a high incidence of hand injuries. Despite providing its workforce with ANSI/ISEA 105 A4 cut resistant gloves and strictly enforcing best-practice safety protocols, the plant was experiencing frequent cut-related incidents. These injuries not only impacted employee well-being but also led to lost workdays, reduced productivity, and increased disability-related costs.

Adding to the complexity, the plant had different safety requirements in different operational areas. Some high-risk sections required ANSI/ISEA 105 A9 protection, while others only needed ANSI/ISEA 105 A6. Without a clear visual system, workers frequently mixed up the gloves, leading to compliance issues and mismatched protection levels. This confusion created unnecessary risks and made it difficult for Health & Safety managers to enforce proper PPE usage.

The plant’s safety manager was seeking a more effective solution—one that would not only boost cut protection but also eliminate the glove-mixing problem.

The Solution: The RONCO Safety Assessment (RSA)

Recognizing the need for a change, the safety manager partnered with RONCO to conduct a comprehensive RONCO Safety Assessment (RSA). The assessment involved:

• A detailed analysis of operational hazards.

• A review of the existing PPE program.

• An evaluation of specific tasks performed by workers in different plant zones.

Following the assessment, RONCO’s safety expert recommended two crucial changes:

1. Upgrading cut protection in the highest-risk areas from the current A4 gloves to RONCO’s 69-9452 ANSI/ISEA 105 A9 cut resistant gloves.

2. Implementing RONCO’s color-coded cut resistance system—assigning unique glove colors to each cut level (A6 vs A9), making it visually obvious when a worker was wearing the wrong glove for their zone.

The A9 rating offers a significantly higher level of cut protection, making it ideal for handling sharp, heavy-gauge metal. Meanwhile, the color-coding strategy made compliance effortless and immediate, eliminating the glove-mixing issue overnight.

Immediate Results and User Feedback

The transition brought immediate and measurable improvements:

• Zero hand injuries in the first week of implementation.

• Perfect compliance with glove assignments across all zones thanks to the color-coded system.

• Improved worker confidence knowing they were always using the correct glove for their environment.

Workers praised several key features of the new RONCO gloves:

• Exceptional Dexterity & Grip: Enabled precise handling of metal parts, reducing material drops and improving efficiency.

• Superior Comfort: Breathable, ergonomic design encouraged all-day wear without discomfort, increasing compliance.

• Touchscreen Compatibility: Allowed operation of touchscreen devices without glove removal, keeping hands protected throughout the shift.

Long-Term Impact and Savings

The combined impact of higher cut protection and color-coded compliance was transformative:

• A sustained reduction in injuries across all areas of the plant.

• Zero lost workdays related to cut hazards.

• Simplified safety enforcement, as supervisors could instantly spot non-compliance from a distance.

• Significant cost savings from reduced injury claims and improved productivity.

This case from Ontario demonstrates how the right PPE—combined with an intelligent safety system like RONCO’s color-coded ANSI/ISEA 105 cut resistance program—can transform a high-risk environment into a model of safety, efficiency, and compliance.

Industries That Benefit Most from A9 Cut Resistant Gloves

1. Metal Fabrication & Processing

2. Glass Handling & Manufacturing

3. Scrap & Recycling Facilities

4. Heavy Industrial Manufacturing

5. Construction & Demolition

These are exactly the industries where A9 cut resistant gloves provide the highest return on investment through injury prevention and worker comfort.

The Color Cut Coding Advantage

Selecting the right cut level has historically been a guessing game for workers. RONCO’s Color Cut Coding changes that:

• Black = ANSI/ISEA 105 Cut A9

• Red = ANSI/ISEA 105 Cut A8

• Green = ANSI/ISEA 105 Cut A7

• Blue = ANSI/ISEA 105 Cut A6

• Orange = ANSI/ISEA 105 Cut A5

This visual system eliminates confusion, speeds up glove selection, and improves compliance – especially in multi-hazard worksites where glove changes are frequent.

Why the PrimaCut™ 69-9452 is the Ultimate A9 Cut Resistant Glove

The PrimaCut™ 69-9452 isn’t just another glove – it’s the final word in cut protection. It was designed with the worker in mind, balancing the highest safety standard with real-world usability.

When a glove can satisfy:

• The worker (comfort and performance)

• The safety manager (maximum protection)

• The procurement team (value and longevity)

• The distributor (healthy margins)

… it’s not just PPE. It’s a business solution — and one of the most reliable A9 cut resistant gloves you can choose.

Experience these gloves by requesting trial samples today. Visit the PrimaCut 69-9452 product page to learn more. If you have any questions, contact us at 905-660-6700 / contactus@roncosafety.com

Abhinav Sridhar

Senior Product Development Manager

RONCO Safety

Watch these gloves in action below!

SIGN UP FOR OUR

NEWSLETTER

Learn how sustainable cut resistant sleeves deliver reliable arm protection comfort and durability while supporting environmental goals.

Match cut risk to the right cut level with PRIMACUT™ cut resistant gloves for manufacturing, designed for safety, dexterity & compliance.

Discover PRO-TEC™ NIOSH approved N95 respirators. Available in valved and non-valved options for comfort, compliance & 95% filtration.

Head Protection

Head Protection Hand Protection

Hand Protection Body Protection

Body Protection Sustainable Protection

Sustainable Protection VendPack®

VendPack®  RetailPack

RetailPack