-

Call us

-

Send Us Mail

What are Different Types of Coating and Liners for Cut-Resistant Gloves and Their Purpose

When it comes to workplace safety, protecting your hands is crucial. One of the most effective ways to safeguard your hands is by using cut-resistant gloves. These gloves are essential for industries, and in general, where sharp tools and materials pose a constant risk. But what makes these gloves so effective? The secret lies in their cut-resistant liners and coating. In this article, we’ll explore the different types of cut resistant liners and compatible coatings for gloves and their specific purposes.

Understanding Cut-Resistance

Definition and Significance

Cut resistance refers to the ability of a material to withstand cuts or lacerations from sharp objects. This is crucial in various industries, including construction, manufacturing, and food processing, where workers are regularly exposed to cutting hazards.

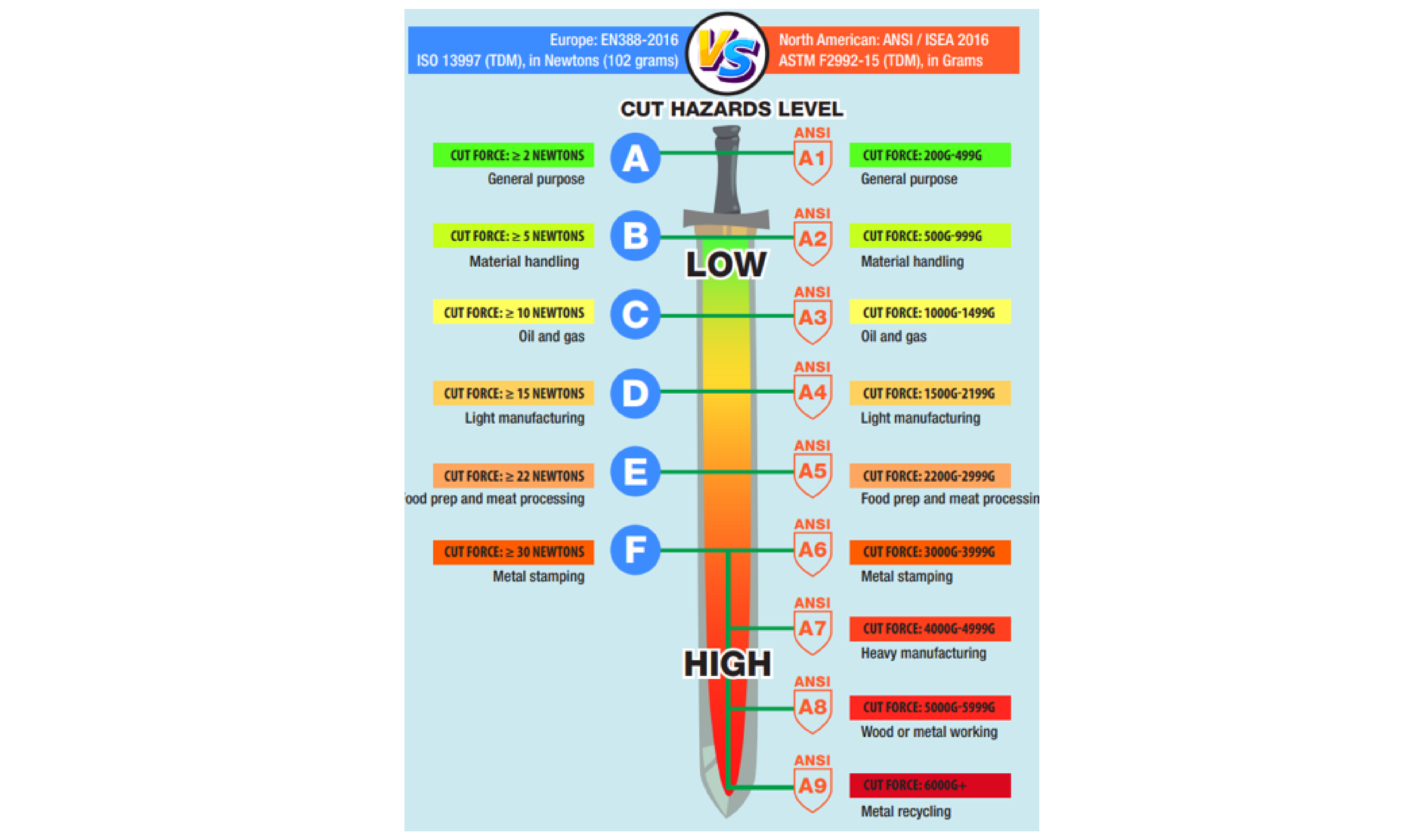

How Cut-Resistance is Measured

Cut resistance is measured using standardized tests such as the ASTM (American Society for Testing and Materials) and EN (European Standard) tests. These tests determine the glove’s resistance level by applying a controlled amount of force and observing how the material withstands it.

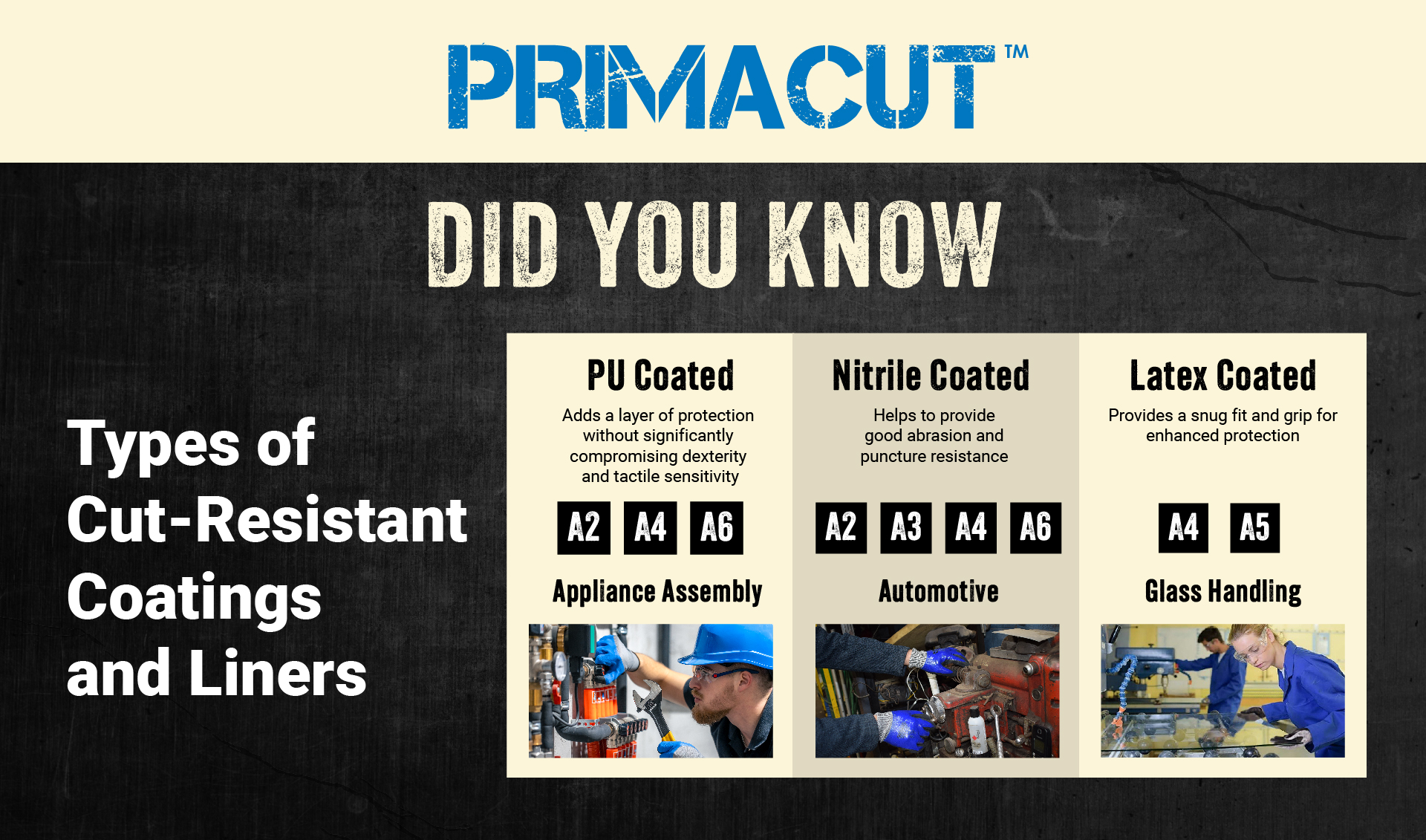

Type of Coating Materials

The effectiveness of cut-resistant gloves for specific tasks largely depends on the coating material used. Different coatings provide varying levels of protection and grip, making them suitable for specific tasks and environments.

Polyurethane (PU)

Properties and Benefits

Polyurethane (PU) coating is known for its excellent dexterity and flexibility. It provides a snug fit, allowing for precise movements and reducing hand fatigue. PU-coated gloves are also resistant to oils and greases, making them ideal for handling small, slippery objects.

Applications/End User Industries

PU-coated gloves are perfect for industries like electronics assembly, automotive, and general maintenance, where both dexterity and cut resistance are crucial.

Nitrile

Properties and Benefits

Nitrile coating offers superior puncture resistance compared to other coatings. It is also resistant to oils, fuels, and certain chemicals. Nitrile provides a good grip, both in wet and dry conditions, and maintains flexibility over a wide temperature range. Nitrile coating can be of different types – Flat Nitrile, Sandy Nitrile, Foam Nitrile, and MicroFoam Nitrile.

Applications/End User Industries

Nitrile-coated gloves are suitable for industries such as automotive, metal stamping, and food processing, where handling sharp and oily objects is common.

Latex

Properties and Benefits

Latex coating is known for its excellent grip and elasticity. It provides a comfortable fit and high resistance to abrasion and cuts. However, latex can cause allergic reactions in some individuals, which is a factor to consider.

Applications/End User Industries

Latex-coated gloves are ideal for construction, landscaping, and warehousing, where a strong grip and durability are necessary.

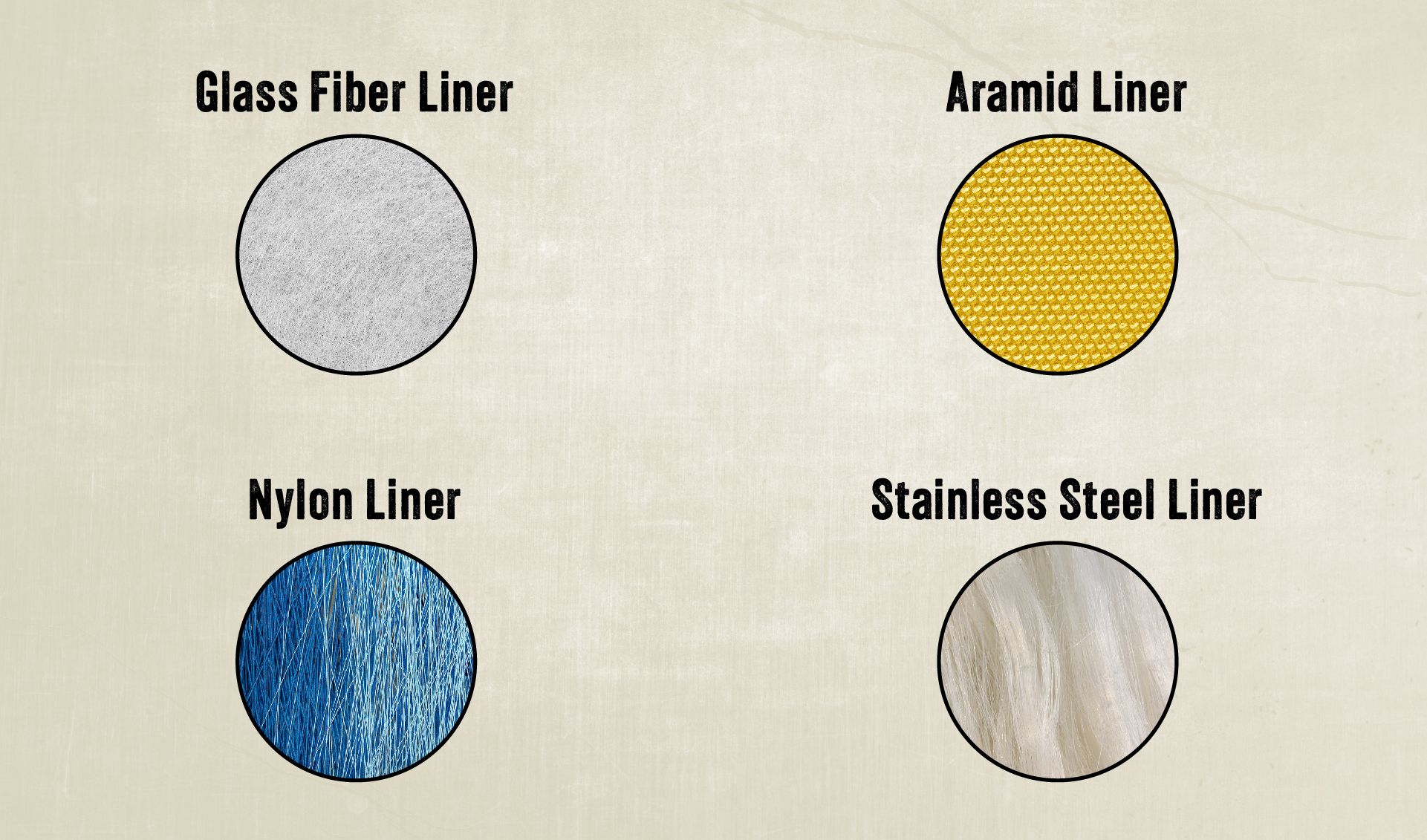

Types of Cut-Resistant Liners

A glove liner is the inner layer of a glove that provides additional comfort, and protection. The liner of a glove is just as important as the coating. Liners provide the foundational cut resistance and additional comfort to the wearer. Different materials offer various levels of protection and suitability for different tasks.

Glass Fiber

Properties and Benefits

Glass fiber liners enhance the cut resistance of gloves significantly. These gloves are durable and provide excellent protection against sharp objects while maintaining flexibility.

Applications/End User Industries

Glass fiber liners are ideal for metal fabrication, construction, and recycling industries, where high cut resistance is paramount.

Aramid

Properties and Benefits

Aramid fibers, like Kevlar, are renowned for their high strength and thermal stability. Aramid liners offer exceptional cut and heat resistance, making them suitable for high-risk environments.

Applications/End User Industries

Aramid liners are used in industries such as glass handling, metal fabrication, and welding, where both cut and heat protection are required.

Nylon

Properties and Benefits

Nylon liners provide good cut resistance combined with excellent flexibility and comfort. They are lightweight and can be worn for extended periods without causing discomfort.

Applications/End User Industries

Nylon liners are commonly used in electronics assembly, automotive industries, and other tasks that require a combination of dexterity and protection.

Stainless Steel

Properties and Benefits

Stainless steel fibers are woven into liners to provide the highest level of cut resistance. These liners are incredibly durable and can withstand severe cutting hazards.

Applications/End User Industries

Stainless steel liners are suitable for extreme cutting hazards such as those found in meat processing, metalworking, and glass handling industries.

Choosing the Right Coating and Liner for Your Needs

Factors to Consider

When selecting cut-resistant gloves, consider the following factors:

The Level of Cut Resistance Required: Assess the hazards in your work environment. High-risk areas may require gloves with a higher cut-resistance level.

The Type of Materials and Tools Handled: Different tasks require different levels of dexterity and grip. For example, handling oily parts may need nitrile-coated gloves.

The Work Environment: Consider whether your work conditions are wet, dry, or oily, as this affects the choice of coating and liner.

Any Potential Allergies: Some materials, like latex, can cause allergic reactions. Be mindful of any allergies among your workforces.

RONCO’s Role in Providing Quality PPE

As a world-class PPE manufacturer, RONCO offers a wide range of cut-resistant gloves with various coatings and liners to meet the specific needs of different industries. RONCO’s commitment to quality and safety ensures that their gloves provide superior protection, durability, and comfort. By choosing RONCO, you can trust that you are getting high-performance gloves designed to keep your workforce safe.

RONCO’s cut-resistant gloves are available in various ANSI levels, ensuring that you can find the appropriate level of protection for your specific needs.

Try Ronco’s Cut-Resistant Gloves for Free!

Conclusion

Cut-resistant gloves are a vital component of workplace safety, and understanding the different types of coatings can help you choose the right gloves for your specific needs. Each coating offers unique benefits tailored to various applications. By considering factors such as the level of cut resistance required and the work environment, you can ensure that you select the most appropriate gloves to keep your hands safe.

Frequently Asked Questions

What industries benefit most from cut-resistant gloves?

Industries such as construction, automotive, food processing, and metal fabrication benefit significantly from using cut-resistant gloves due to the high risk of cuts and lacerations.

How often should cut-resistant gloves be replaced?

Cut-resistant gloves should be replaced when they show signs of wear and tear, such as holes, thinning, or loss of elasticity. Regular inspection is crucial to ensure continued protection.

Can cut-resistant gloves protect against other hazards?

While cut-resistant gloves are primarily designed to protect against cuts, some coatings also offer protection against punctures, abrasions, and certain chemicals, depending on the material. Check out our guide for more information.

Can cut-resistant gloves be used in food handling?

Yes, certain cut-resistant gloves can be used in food handling. Just ensure the glove meets the relevant food safety standard and regulation. PrimaCut™ 69-510 is a good example of industrial glove that is used in food industry

How do I choose the right size of cut-resistant gloves?

Choosing the right size is crucial for comfort and protection. Measure the circumference of your hand around the palm area and refer to the manufacturer’s sizing chart. Properly fitted gloves should feel snug but not restrictive.

What makes RONCO a trusted name in PPE?

RONCO is a world-class PPE manufacturer known for its commitment to quality, innovation, and safety. With a wide range of cut-resistant gloves designed to meet the needs of various industries, RONCO ensures that each product provides superior protection, durability, and comfort. Partnering with Ronco means trusting a brand that prioritizes the safety and well-being of its users.

Try Ronco Gloves – Free Sample Available Now!

SIGN UP FOR OUR

NEWSLETTER

Learn how sustainable cut resistant sleeves deliver reliable arm protection comfort and durability while supporting environmental goals.

Match cut risk to the right cut level with PRIMACUT™ cut resistant gloves for manufacturing, designed for safety, dexterity & compliance.

Discover PRO-TEC™ NIOSH approved N95 respirators. Available in valved and non-valved options for comfort, compliance & 95% filtration.

Head Protection

Head Protection Hand Protection

Hand Protection Body Protection

Body Protection Sustainable Protection

Sustainable Protection VendPack®

VendPack®  RetailPack

RetailPack